News

Heavy Duty Shipping Boxes: Which Businesses Need Them

Shipping boxes do more than hold products. The right boxes protect your items, reduce damage costs, and keep customers happy. Heavy duty shipping boxes solve specific problems for businesses that ship valuable, fragile, or heavy items.

What Makes a Box Heavy Duty

Standard shipping boxes use single-wall cardboard with a test rating around 200 pounds. Heavy duty boxes feature double-wall or triple-wall construction with test ratings from 275 to over 1,000 pounds.

The difference shows up when boxes face real shipping conditions. As mentioned in a Forbes article, the average package is dropped 17 times during shipping. Heavy duty boxes survive these drops while protecting contents.

Thicker walls mean better stacking strength. Warehouses stack boxes high on pallets. Weak boxes on the bottom collapse and damage products. Heavy duty boxes hold weight without crushing.

E-Commerce Businesses Shipping High-Value Products

Online stores shipping electronics, glassware, or collectibles need heavy duty boxes. When your product costs hundreds or thousands of dollars, spending extra on packaging makes sense.

Customer returns cost money. Damaged items during shipping lead to refunds, replacements, and lost profits. Strong boxes reduce damage rates and protect your margins.

Reviews matter for online businesses. Customers who receive damaged products leave negative reviews. These reviews hurt future sales more than the cost of better boxes.

Electronics retailers face special challenges. Computers, monitors, and audio equipment contain sensitive components. Standard boxes fail to protect these items during rough handling.

Wholesale Distributors Moving Bulk Orders

Distributors ship large quantities to retailers and other businesses. These orders often weigh 40 to 70 pounds per box. Standard boxes break under this weight.

Heavy duty boxes handle bulk orders safely. Stronger walls and better glue hold together when boxes carry maximum weight. This strength prevents costly spills and product loss.

Distribution centers move boxes multiple times before delivery. Forklifts, conveyor belts, and hand trucks stress packaging. Boxes must survive rough handling at several stops.

Manufacturing Companies Shipping Parts and Components

Manufacturers ship metal parts, tools, and machinery components. These items have sharp edges and significant weight. Regular boxes tear and puncture easily.

Industrial parts often cost more to produce than to ship. Protecting these parts during transit saves money and maintains customer relationships. Heavy duty boxes prevent damage to expensive components.

Machine shops and metal fabricators deal with oil and moisture. Heavy duty boxes resist moisture better than standard options. This protection keeps parts clean and rust-free during shipping.

Businesses Shipping Internationally

International shipments face longer transit times and more handling points. Packages traveling overseas get loaded and unloaded multiple times. They sit in warehouses and travel through different climates.

The International Safe Transit Association notes that packages crossing borders experience 30% more handling than domestic shipments. This extra handling requires stronger packaging.

Customs inspections add stress to packages. Officials open boxes for inspection and repack them. Heavy duty boxes survive this extra handling without falling apart.

International returns cost even more than domestic ones. Shipping damaged products back across borders wastes time and money. Better boxes prevent these expensive problems.

Food and Beverage Companies

Food distributors ship canned goods, bottled products, and packaged foods. These items weigh more than typical packages. Glass bottles need extra protection.

Restaurant suppliers deliver bulk orders to commercial kitchens. Cases of ingredients must arrive intact. Broken jars or crushed packages disrupt kitchen operations.

Specialty food companies ship gift baskets and premium products. These high-margin items justify heavy duty packaging. The presentation matters as much as the contents.

Auto Parts Retailers and Suppliers

Auto parts range from small sensors to large body panels. Many parts have awkward shapes and sharp edges. Standard boxes fail to contain these items safely.

Brake rotors, batteries, and engine components weigh significant amounts. Heavy duty boxes handle this weight while protecting the contents from impact damage.

Auto parts customers need products immediately for repairs. Damaged parts during shipping delay repairs and frustrate customers. Strong packaging ensures parts arrive ready to install.

Furniture and Home Goods Businesses

Furniture retailers ship items with multiple pieces and hardware. These shipments need boxes strong enough to hold weight while protecting surfaces from scratches.

Home improvement stores send tools, fixtures, and building materials. Construction products have weight and bulk requiring heavy duty packaging.

Lighting fixtures combine weight with fragility. Heavy bases and delicate shades need boxes offering both strength and cushioning space.

Medical Supply Companies

Medical equipment and supplies require careful handling. Diagnostic tools, testing equipment, and instruments cost thousands of dollars. Damage during shipping affects patient care.

Pharmaceutical distributors move products requiring temperature control and physical protection. Heavy duty boxes provide better insulation and structural integrity.

Medical supplies often ship to urgent situations. Hospitals and clinics need products arriving intact and on time. Reliable packaging supports critical healthcare operations.

Cost Considerations and Return on Investment

Heavy duty boxes cost 30% to 100% more than standard boxes. A regular box might cost 75 cents while a heavy duty version costs $1.50. This difference seems small until you calculate annual volumes.

Damage costs far exceed packaging costs. Replacing a $200 product costs more than spending an extra dollar on a better box. Insurance claims, customer service time, and lost customers add hidden costs.

Businesses shipping 1,000 packages monthly spend an extra $750 on heavy duty boxes. If better boxes prevent just four damaged shipments worth $200 each, you break even. Most businesses prevent far more damage.

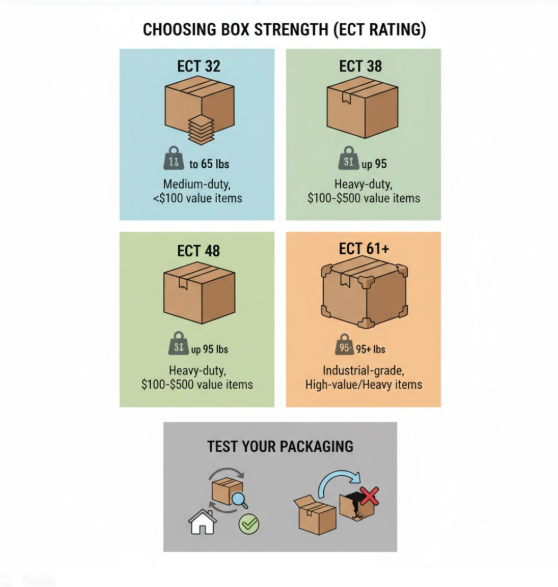

Choosing the Right Box Strength

Edge Crush Test (ECT) ratings measure box strength. ECT 32 handles up to 65 pounds, while ECT 48 supports 95 pounds. ECT 61 and higher ratings suit heavy industrial applications.

Match your box rating to your product weight and value. Shipping a 10-pound item worth $500 needs different protection than shipping a 50-pound item worth $50.

Test your packaging before committing to large orders. Ship samples through your normal channels and inspect them on arrival. This testing reveals weaknesses before they cause customer problems.

Environmental Factors in Box Selection

Weather affects shipments sitting on loading docks or in unheated trucks. Moisture weakens cardboard boxes. Heavy duty boxes resist water damage better than standard options.

Temperature changes during shipping cause condensation inside boxes. Products sensitive to moisture need the extra protection heavy duty boxes provide.

Storage and Handling Benefits

Heavy duty boxes stack better in warehouses. You store more products in less space when boxes hold their shape. This efficiency reduces storage costs.

Employees prefer handling sturdy boxes. Boxes falling apart create safety hazards and slow down operations. Strong boxes improve warehouse productivity.

Building Customer Trust Through Quality Packaging

Customers judge your business by how products arrive. Premium packaging signals product quality and business professionalism. This perception affects repeat purchases and referrals.

Unboxing experiences matter for brand perception. Sturdy boxes that open easily and protect contents create positive impressions. These details influence customer loyalty.

Your packaging represents your brand when you’re not there. The box is often the first physical interaction customers have with your business. Make it count with packaging showing you care about product protection.

Heavy duty shipping boxes serve businesses where product value, weight, or shipping conditions demand extra protection. The upfront cost pays back through reduced damage, happier customers, and stronger brand reputation. Evaluate your shipping needs honestly and choose boxes matching your requirements rather than defaulting to the cheapest option.

-

Rappers1 year ago

Rappers1 year agoGloRilla Net Worth: Height, Age, Bio, Real Name & Career

-

Businessman1 year ago

Businessman1 year agoBrandon Fugal Net Worth: How Rich is Skinwalker Ranch Owner?

-

Rappers3 years ago

Rappers3 years agoBigXthaPlug Net Worth: Height, Age, Real Name & Career

-

TV Stars1 year ago

TV Stars1 year agoKaleb Cooper Net Worth: How Rich is the TV Star Actually?

-

Internet Stars3 years ago

Internet Stars3 years agoMufti Menk Net Worth: How Rich is the Islamic Speaker Actually?

-

TV Stars1 year ago

TV Stars1 year agoCarla Diab Net Worth: How Rich is the TV Star Actually in 2025?

-

Businessman2 years ago

Businessman2 years ago7 Proven Lead Generation Strategies To Implement in 2023

-

Rappers1 year ago

Rappers1 year agoDD Osama Net Worth: Height, Age, Real Name, Career & More

You must be logged in to post a comment Login